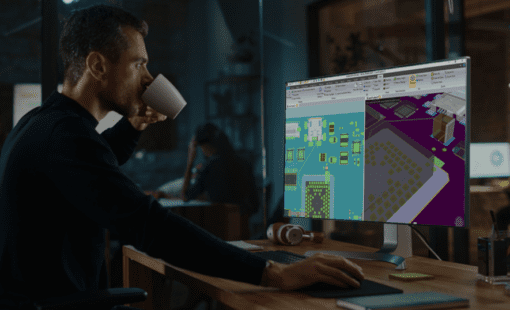

In modern electronics development, seamless integration of electrical and mechanical design is no longer a luxury – it is a fundamental requirement for project success. eCADSTAR provides a native 3D environment that bridges the gap between ECAD and MCAD, ensuring that design decisions are validated in real time to avoid costly downstream errors in 2026.

Precision 3D Model Alignment

The 3D design journey begins with the effortless assignment of components. eCADSTAR enables users to switch between 2D and 3D views quickly and intuitively, significantly speeding up the layout process.

Key advantages of the alignment workflow include:

- Unified 3D Model Manager: Select and assign components directly from the library with real-time visual previews for immediate confidence.

- Intuitive Navigation: A modern, consistent menu structure with helpful tooltips across all applications.

- Flexibility: Support for multiple reference points allows for fast and adaptable 3D placement.

Once initial alignment is achieved, the software makes it simple to move entire components or fine-tune positions, including Z-axis height adjustments, with minimal effort. Native 3D views and various measurement functions ensure that every model sits perfectly on its pads. Furthermore, quick access to functions like ‘Reload Part’ allows designers to update 3D models within the design environment at any time.

Mechanical Integration via the MOO

Integrating complex 3D mechanical objects for MCAD collaboration is achieved efficiently through the Mechanical Object Organizer (MOO). This specialized tool allows for the simultaneous visualization of both the mechanical part and the PCB design. For a better overview, elements can be shown or hidden with a single click.

Precise alignment is achieved by setting multiple connection points on both the PCB design and the mechanical object. During the relocation process, blue guide lines illustrate the target position, ensuring high-precision placement. After verifying the alignment, the mechanical body becomes visible within the PCB Editor environment. eCADSTAR provides numerous display optimization functions to ensure the designer always maintains a clear overview of the spatial relationship between components.

Automated Collision Analysis

To ensure physical manufacturability, eCADSTAR’s native 3D Collision Check identifies contact points between the PCB design and mechanical objects with high accuracy. Users can precisely select specific areas or a wide range of object types for verification, while the system provides helpful tips, alerts, and automatically suggests the most logical next steps.

Identified collisions are highlighted with custom colors and a flashing effect for immediate visual recognition. All findings are logged in a comprehensive report that can be enhanced with comments and additional information. This report can then be shared with the development team via export and import functions, facilitating a collaborative resolution process.

Advanced Clearance Validation

In addition to detecting direct contact, the 3D Clearance Check validates that user-defined minimum distances between elements, such as connectors, nets, and mechanical objects, are strictly maintained. All rules can be created, adjusted, and saved as reusable rule sets within a single management window, which can also be shared with the team.

The intuitive interface allows the user to jump directly from the report to the specific object with the issue. For instance, if a connector is identified as being too close to a mechanical object, the conflict can be resolved by importing a modified IDF file or a IDX file to update the position. A subsequent 3D clearance check ensures that the design now meets all specified requirements and adheres to the defined safety standards.

State-of-the-Art STEP Export

The STEP export is the essential link to the mechanical engineering department for final verification and modifications. eCADSTAR simplifies this process into a few logical steps. A centralized interface allows users to define file names and configure all custom export parameters and options.

A significant advantage in 2026 is the full support of design variants during the export process. By utilizing the latest STEP versions, eCADSTAR ensures maximum compatibility with all major MCAD applications without the need for additional adjustments.

3D Multiboard Integration

For complex projects, 3D Multiboard Integration allows for the simultaneous connection and validation of multiple PCB designs. Using the MOO, team-generated designs can be imported along with their mechanical housings into the current project layout. Blue construction lines and suggested reference points assist in precise positioning within the overall system.

To enhance clarity, eCADSTAR offers comprehensive options to customize the transparency and color display of individual elements. This holistic approach ensures that all components fit perfectly within the final enclosure before data is exported for the MCAD department’s final verification. Through this deep integration, eCADSTAR provides a consistent workflow for all 3D model varieties, ensuring smooth cooperation across all design disciplines.

Ready to Unify Your 3D Design Workflow?

The advanced capabilities described in this article, from precise 3D Model Alignment and automated Collision Analysis to seamless Multiboard Integration, are designed to eliminate the boundaries between ECAD and MCAD. To leverage the full power of these native 3D features and ensure the technical reliability of your designs in 2026, we offer specialized solution packages tailored to your needs.

Experience the complete range of high-end features, including advanced clearance validation and state-of-the-art STEP export, by exploring the eCADSTAR Advanced 3D Bundle.

Not sure which eCADSTAR bundle fits your specific requirements? You can find a comprehensive overview and comparison of all five available software configurations in our eCADSTAR PCB Features Matrix. Take the next step toward a truly unified design environment today.